ONLINE COUNSELLING

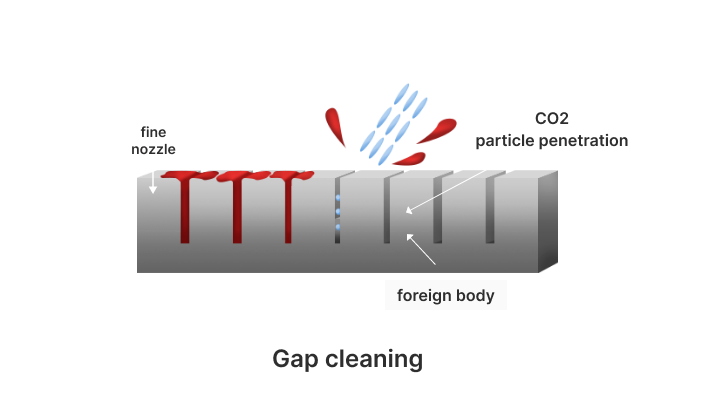

We will solve your concerns with ESG’s unique precision dry cleaning technology.

(Contact number for counseling) +82-70-7658-0902

GALLERY

Click here to view more videos

in the Gallery

BLOG

Click here to view more materials

in the BLOG